Well, after a long detour in another topic (Problems with Cut Opening in a DC with subcomponents that I thought should cut, but don't) I’ve got something working, for SU v2014 or later.

There are eight dynamic components, one for each thickness of board (19, 25, 28, 32, 35, 38 and 44mm, or approx 3/4". 7/8", 1", 1 1/8", 1 1/4", 1 3/8", 1 1/2" and 1 3/4"). That covers the majority of finished thicknesses of planed softwood in UK and US/Canada.

Each component offers the same choice of four screw sizes (28, 32, 38, or 44mm, or approximately 1 1/4", 1 1/2", 2" and 2 1/2") or no screw, or screw head only. Each component is set by default to use the longest screw that can be used in the board the screw is going into if it is the same thickness as the board with the pocket hole. You can use longer screws in a thicker screwed-into board.

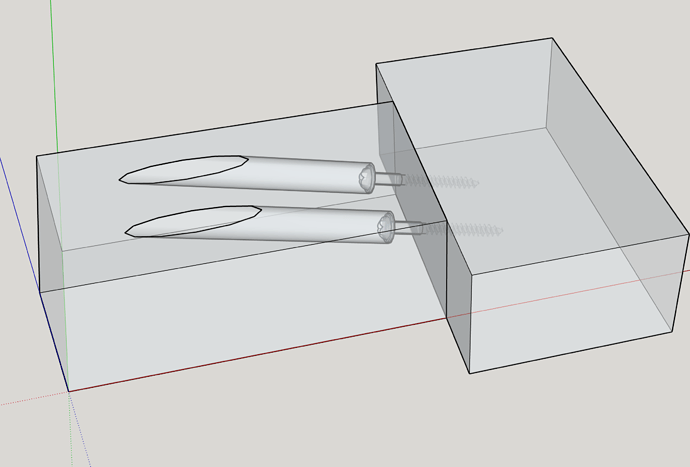

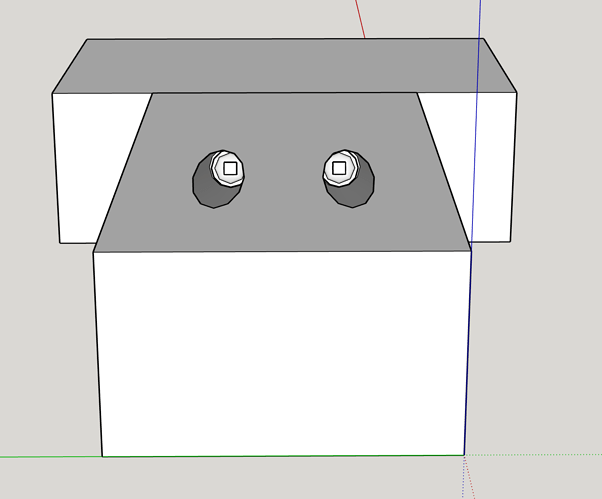

Here is the set, embedded in a board. Because the pocket holes are embedded in a component, you can just open the file, then either explode and delete the board, or delete the lot. (In this case, don’t import the file, just open it). The pocket holes and screws will appear in your component browser, and you drag them out from there into any board you have open for editing (that’s important - Cut Opening only works in the particular face into which the component origin and the hole opening are placed).

If you are just using one board thickness, use at least one of the right size of component, then Purge Unused from the Component Browser.

Kreg pocket holes and screws DC v2014.skp (244.8 KB)

I’ll put it on the 3D Warehouse shortly, but Claire (@EosDawn), try it first if you would, please.

I found that to use it in versions as old as 2014 one might need to update the Dynamic Component extension, and one may have to do it manually for 2014, since I found that even downloading the latest v1.7.rbz file I couldn’t install it from Extension Manager/Install extension. I needed to change the file extension to zip, extract a folder and file from that, and copy them into the Sketchup 2014 Plugins folder. Not for the faint hearted.

But it works in SU 2016 which has the DC Extension v1.4.2 without

If one doesn’t update the extension, on v2014 whenever you try to edit any component by double clicking on it, you get two error messages. It sort of works if you use R-click, Edit Component, but that’s not a pleasant way to work.

But it works without any bother in v2019 - or at least it did for me! Hope you have the same experience.