Hi, is there a way to make cutout on the board stay in given possition and not to scale even board size is changed.

Cutout 1 always need to stay in a corner and stay same size.

Cutout 2 needs to be moved up and down, but not to scale its size.

Any help is much appreciated.

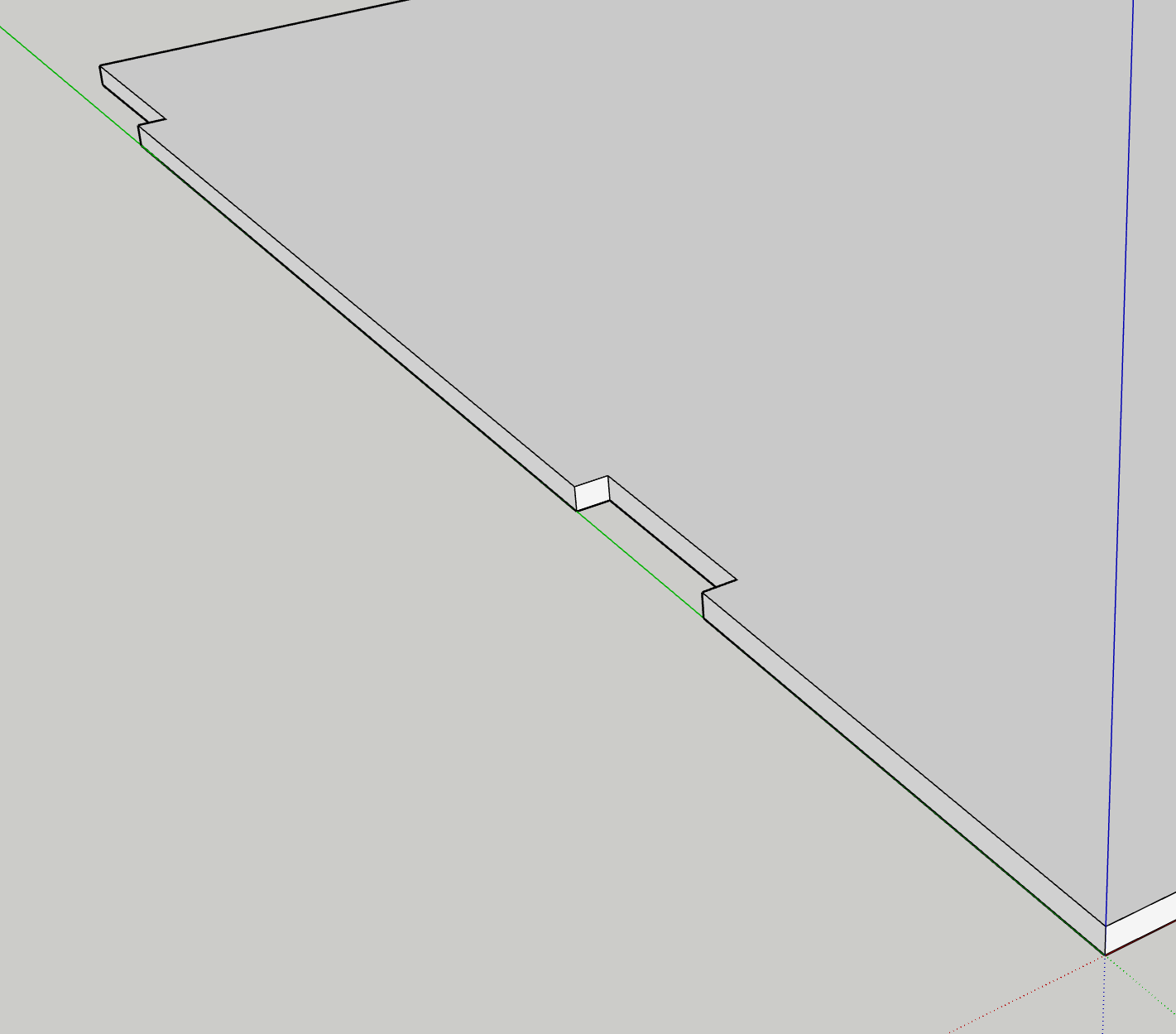

You would need to split the board into separate components so the parts with the notches don’t get scaled when the board gets resized.

Here’s a simple set up.

The corner notch and side notch components would only be moved with a dimension change while the rest will be scaled. The component between the notches will also need to move with dimension change.

Would any of cutlist extensions still use whole board as a single part? My goal is to have dynamic cabinet with these cutouts, I guess only option is to make buch of different size cabinets and import the ones I need?

The cutlist extensions would take the lowest level components. You could explode the component after getting the size correct so the entire panel is one component.

How many panels need holes like this? My inclination would be to skip the holes in the component and add them in the right places when needed.

What Dave presented will do exactly what you ask. Just hide the edges (Erase tool hold shift and click edges to hide) of the separate component parts. It will appear as one solid panel.

Mark is right. If you do split it as I show you can hide the edges and faces between the components so it looks like a single object. I didn’t do that for my simple example so that you could easily see how they are split.

Usually about 10cabinet, so 20 cabinet sides. About 6 cabinets with both cutouts and 4 with just top cutout. Also I give drawings to CNC place to have boards cut for me, therefore everytime cabinet sizes change I have manually change cutout size and position. And looks like I will have to convert file to DXF for them in near future, that’s why lookimg for quicker way to do it, without going away from Sketchup.

So Mark has shown the set up I described as a DC and maybe that will work for you. Instead of hiding the faces in the seams, you could delete them and just hide the edges. Then, I would suggest your workflow after placing the components and finalizing the dimensions would be to explode the component so it becomes a single object and then run CleanUp3 to merge coplanar faces to get rid of the unneeded edges. You don’t need those edges becoming tool paths after all.

Aaron did a series on Skill Builder (YouTube) for Dynamic components for a picture frame (8 part series). He shows how to set length and position attributes based on resizing changeable portions. Its a great watch to get all these pieces sizing correctly

I will try and see how it will work.

Thanks a lot to you both. ![]()

Unistrut Dynamic Component - Model - 3D Warehouse

You might check this DC I made. It has set size holes that copy when the length is resized. They redraw after sizing is complete. but might help if keeping the substrate a single piece is mandatory. Mine only deals with one axis stretching, but it is a start. Since the top notch always stays in that spot is easy to program. The bottom notch Z value can be set to LenZ value of entire panel less the lenZ of self (for vertical panels).