My apologies, Dave. I moved my gmail icon and completely forgot about it.

I have no idea why the 3d print went wrong, or why it went right after exploding the group. It hasn’t happened again since then.

Generally I prefer to use threads as printed. I use Chinese stainless steel set screws and bolts in M4, 5, 6, 8 and 10, but tend to tap M4 and M5 nowadays.

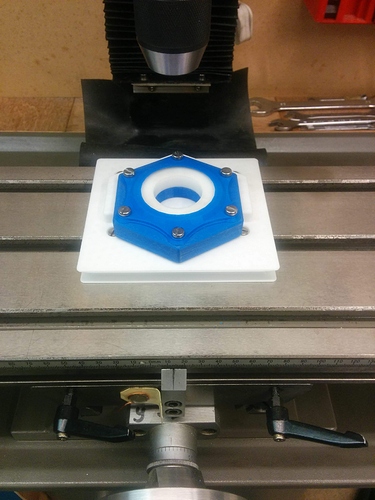

Oh, yeah. Good spot. I seem to have gone a bit gender diasphoric with my thread forms. I used them in a workholding faceplate for my lathe. Let’s just say I had a senior moment and move on, can we?

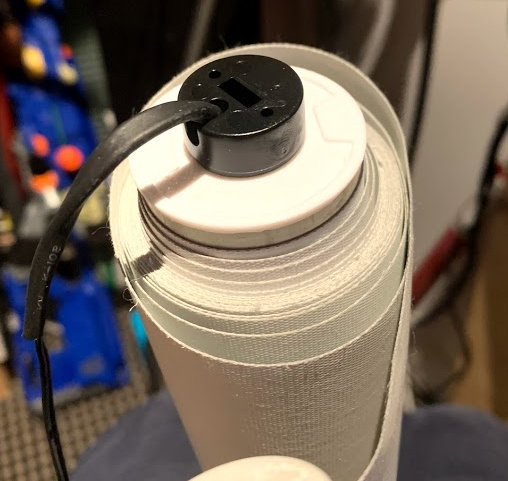

My rule of thumb with 3d printing in general is to use it when I’m happy with plus or minus a tenth of a millimetre accuracy. So I find it useful on my milling machine and lathe for machining plastic components. The attached photo is where I was about to cut six splines into a modified stock plastic crown gear.

The only thread dimension that needs to be accurate is the pitch. Simply scale the other two dimensions by trial and error. I like the thread to tighten without binding so I can bring the mating faces together and then pull them tight with a final eighth or quarter turn without fear of stripping the threads. For slotted or pozi fasteners, I like ten threads. As for spanners, twenty threads seems about right, although I’m only guessing. A major drawback with 3d prints is layer adhesion, so the limiting factor is the weakness of the material. At twenty per cent infill, you’d be winding your bolt into the material and crushing it before stripping the threads.

The dark art that is 3d printing means that as you change your material, hotend temperature, layer height or any one of many variables, the thread just isn’t right any more. You can’t draw one thread that is going to work all the time. The one thing that never changes, though, is the pitch. For me, 3d printed threads in M6, M8 and M10 definitely work, and when you’ve got the diameter right for your particular application, you can be sure the threaded hole is right where it is supposed to be, within the limits of your machine. That’s the best possible, and when it is all done, it’s difficult to avoid being satisfied with the effort involved.

Thank you for your response. Again sorry for not responding sooner.