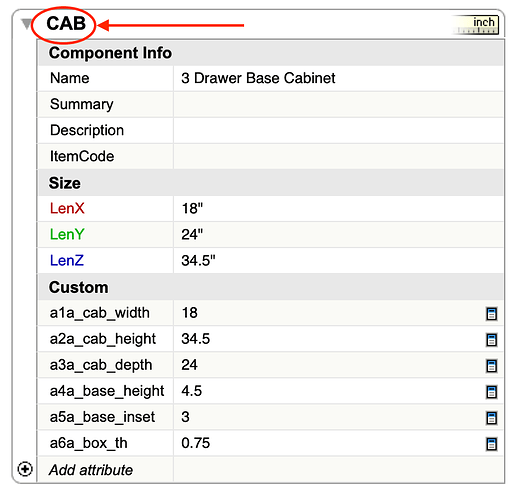

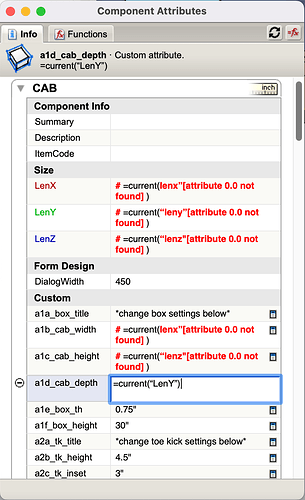

I’m getting ready to embark on the journey of creating dynamic component asset libraries for my design company. I have experience building some DC’s for windows, doors, and trim, but need to start from scratch as the window DC’s I made are too file heavy (I used the cad profiles from the manufacturer to create the extrusions I made the parts from and there are a lot of lines and curves to them). I am looking for advice for naming standards and organization from anyone with experience on what works the best. For example, should I name custom attributes with a letter/number system like “a1a_attribute name” or a double letter system like “aa_attribute name” or some other system that works well? Basically just wanting to get the systematization right before putting the weeks of work in on this. Also, when naming component headers, is there a reason why I should name things differently for each component type or can many of the names be the same across different components? For example, if I am creating a casement and an awning window, should the parts be named with the prefix WIN_CAS_(Part Name) or WIN_AWN_(Part Name) or can they all be simplified with WIN_(Part Name)?

Interested to see what the DC ninja’s have found works the best. Appreciate any feedback!