“They might say that plumbers, electricians, and HVAC installers have a general understanding of the way things need to be run, and don’t need or want a detailed drawing of pipes, wires, or ducts.”

I would say this is more on the money than most of you want to believe. And I say that as someone who worked in the mechanical trades for 35 years running pipe of all sizes from 1/4" instrument tubing to 32 inch steam lines in power plants and refineries. For a residential or light commercial setting most times 3D models of pipe are not needed by the installer. For plumbing a diagram that conforms to code with respect to branch sizes, number of fixtures on a branch, proper venting is more important than seeing a 3D model of the pipe in a wall or ceiling or UG. If you need to for a detail or to work out some tight spot where you are cramming a number of commodities into a tight space and you want to prove it can be done OK. But generally speaking not necessary.

Now in an industrial setting that’s a different story. An extreme example would be running piping in the drywell inside the containment building of a nuclear reactor of which I helped build three. The drywell space is so cramped with pipe and conduit and other equipment you can barely walk. Every square inch is spoken for, there is no leeway and it is rare you get to field run some pipe or conduit. Everything is seismically engineered and you can deviate for location or elevation only by the tolerances given on the drawing which are tight.

Long before (60s and 70s) computers were capable of doing 3D modeling at the level of SU, Fusion, or AutoCAD can today we were putting these monster machines together. Everything was drawn up in 2D or ISO drawings and we had a scale model of the building that was maintained by a couple engineers. There job was to update the model to represent the finished project. This gave everyone a chance to peek and poke at what everything would look like, see what they might have to work around, coordinate installation order of larger pieces of equipment, etc. As changes were made in the field they were responsible to update the model. I don’t remember the scale but the model of the containment building was about 4 feet in diameter and 7 feet high. There were other models of specific areas that required more detail and were built on a larger scale. The actual containment building is about 180 feet in diameter and 230 feet high. But every plant built in the US is different and the building size and layout is unique in some way for most of them, even those that are of the same design and built by the same contractor.

I know this is WOT from that of DWV fittings but I’m just trying to point out this is a level of detail that I don’t think is necessary in real life. Would it be great to have a library of fittings that are dimensionally correct? Yes, that would be awesome and I would want it in my arsenal of tools. But as far as actually building or installing a piping system no, I don’t think it is needed so much for the average residential or light commercial job. A schematic and some elevation and plan views of the piping is usually sufficient. If you need to show pipe in a detail just draw the few fittings you need where necessary.

Now if you were wanting to model some PVC pipe furniture that’s a different story. There you do need accurate representations of the fittings. But if they are not dimensionally correct then don’t bother because while they might look good on paper if the design can’t be replicated in the field it’s wasted ink so to speak. And different manufacturers have been known to make their fittings slightly different in places that don’t affect their usability. The take out of the fitting will be the same but there can be slight differences in the outside of the fitting. LASCO and Charlotte both make PVC fittings, but they can vary slightly in appearance.

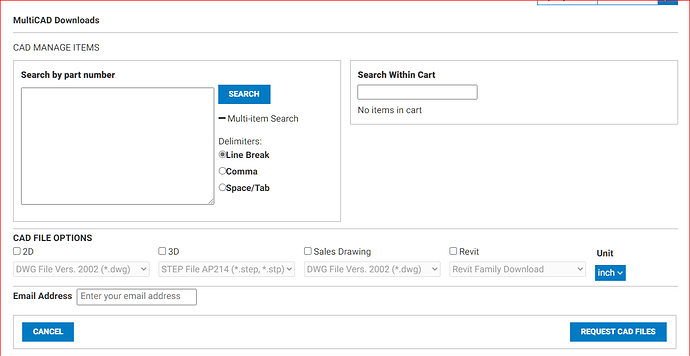

LASCO has some CAD files available by request, and also some you can download immediately as .RFA files.

https://bim.lascofittings.com/rfc?name=all-categories

That’s my opinion anyway.