We are making models in sketchup that we have been printing. One of the models a student has made appears to be solid when we use the solid inspector but upon printing it isn’t. Can someone give me some suggestions as to what to look at? Thank you.

Is it possible for you to share the model? There are a number of possible way to make a non-manifold model. It will be easiest to look at the model to determine the issues.

Here’s the SKP file. I’d love to hear how to fix this.

plane-2.skp (145 KB)

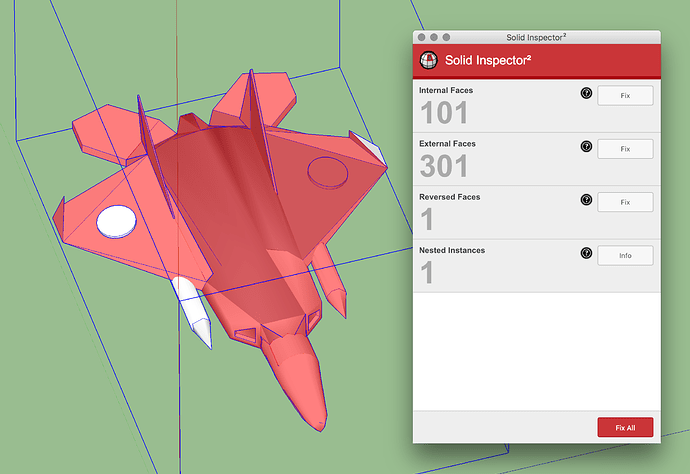

I opened the file and the first issue is that the geometry is not even in a group, and several of the faces are reversed (those blue/gray sections). i ran Sold Inspector2 on it and got the following results:

I would recommend getting a copy of Solid Inspector2, and working through the errors to clean up the model.

https://extensions.sketchup.com/en/content/solid-inspector²

To be honest, there are a LOT of issues. I understand that a student put this together and it looks like they did a good job creating something from nothing, which we love to see! The issue comes in that there are some hard and fast rules about a model that must be followed in order to make it printable. This model has geometry that crosses other geometry, holes in the mesh, single faces (no printable depth to them) and reversed faces throughout.

A good idea may be to try to track all these issues down, and have your student recreate their model and attempt to recreate the model so that it is printable. Another tip would be to model only half of the plane, then make a copy and use the scale command to mirror it, then attach the two halves together (right now, the two sides have different geometry from each other.

It is awesome to see students working on projects like this and I am a huge 3d printing enthusiast, so that makes me happy, too! Unfortunately, preparing a 3d model for printing is very specific and there really are no shortcuts.

Quick tip:

You will know it is a solid group or component when Entity info displays a volume value.

And most of these issues are not subtle and are more general modeling issues than specifically “solids” issues. Extra edges and faces and gaps along edges are very conspicuous and tend to ruin the appearance of the model–never mind about whether it’s solid or not. You should be able to spot these errors easily without even using the Solids Inspector. You (your student) can probably track down most or all of the issues with nothing more than a careful visual inspection. And that is an essential part of the modeling process: to be constantly on the alert for errors and to fix or redo them at once. If you stay on top of it, you can keep the model fairly pristine and head off all but a handful of issues that may affect 3D printing.

But we must be clear about how forgiving a model is of careless errors, especially if it’s going to be 3D printed: we’re talking zero tolerance. No errors; must be perfect. If someone were to go over the model carefully with a determination to fix every visible error, at the end of that it may or may not even be necessary to use the Solids Inspector.

-Gully

Not to mention that the very first line of the Entity Info dialog spells it out in bold letters with either “Solid Group” or “Solid Component” as the class of entity.

-Gully

Well, that’s all good advice. I’ll pass this along to the student and see

if he can try to recreate this. If nothing else, his first attempt at

making a sketchup of his own wasn’t too bad.

Nope, not bad at all! Tell him to keep at it and let us see what he comes up with, next!

A couple of things to be aware of in the model.

The Axes have been changed.

The Field of View is set to 1.32deg whereas the normal FOV is 35deg.

The Plane from tip to tail is just over 600 thousand feet.

It’s certainly a good start.

It often helps to keep a scale figure in the model so you have some idea how big things are.

FYI https://i.materialise.com/blog/5-mistakes-to-avoid-when-designing-a-3d-model-for-3d-printing

I assume you are doing the print so printer may impose requirements also. SU showing as solid is necessary but not sufficient you can print as this link shows. i.materialize also provides service at 3d ware house you may want to check.