Hi Guys,

I ditched my autocad license back in january and im still ironing out my transition over to sketchup completely.

I find it an all around better program to draw in, and i love how accessible the community support is.

That said, im running into a bit of an issue here with a custom audio desk im designing and building.

the frames will consist of laminated 1/8" aluminum buckets. There are proprietary extruded components that connect all of the gear and also act as the lateral structural support.

I need to make sure these extruded components are places as accurately as possible. Im in the process of marking out the pass-through holes for the CNC machine to cut but im having an issue finding the EXACT center of the extruded parts

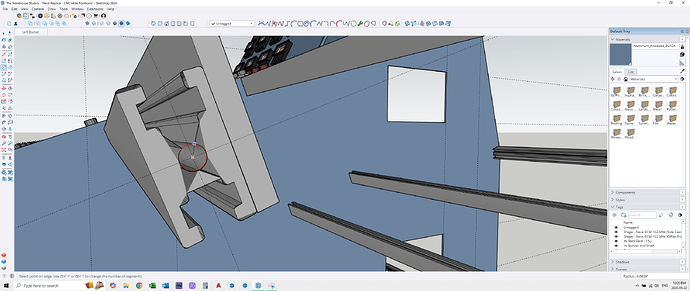

The company we purchased the proprietary parts from in the UK sent me a STEP file of each component. Once i converted and scaled them - i confirmed the measurements in the drawings to the actual pieces i have in hand and they are all correct. But because that circle in the channel (which is where the fastening hardware taps into) is not a complete circle - im not entirely confident to translate those points to the aluminum when indicating where the CNC machine needs to bore a hole. Its also only like a 20 sided circle in the CAD file they provided - so it really throws off the snapping points.

I have “centered” with guidelines to best of my ability - but when i create a circle from that center point (as shown in the screen shots i have provided) you can see that the edges of the circle are slightly off. Were talking about fractions of mm’s … But theres only a 3/16" passthrough in the aluminum - so fractions of mm’s matter at this stage.

Can anyone offer me a seasoned workaround to finding the TRUE center of this incomplete circle?

Thanks for all your help,

Ryan.