Make your screw on the origin but leave out the groove where the driver fits. Move/Copy the screw by the tip to the place where it enters the frame. Use the Rotate tool to set the angle about 25 or 75 degrees off axis. Use the Move tool. and insert the screw up to the head. Push/Pull the top of the grooveless head until the entire elongated radius intersects the edge of the frame’s face. Select the screw with three clicks and select the scissors icon. Open the frame for editing and select Paste in Place. Highlight the frame with three clicks and the screw and frame should all be Highlighted. Select intersect selected. Erase the parts you don’t need to leave the hole for the screw. Now go back and finish making the groove for the screw and make it a component.

Edit: Before inserting the screw use the protractor tool to set the guideline on the correct angle. Use that guideline when inserting the screw.

The way I would go about modeling that depends on what you meant. So, please clarify:

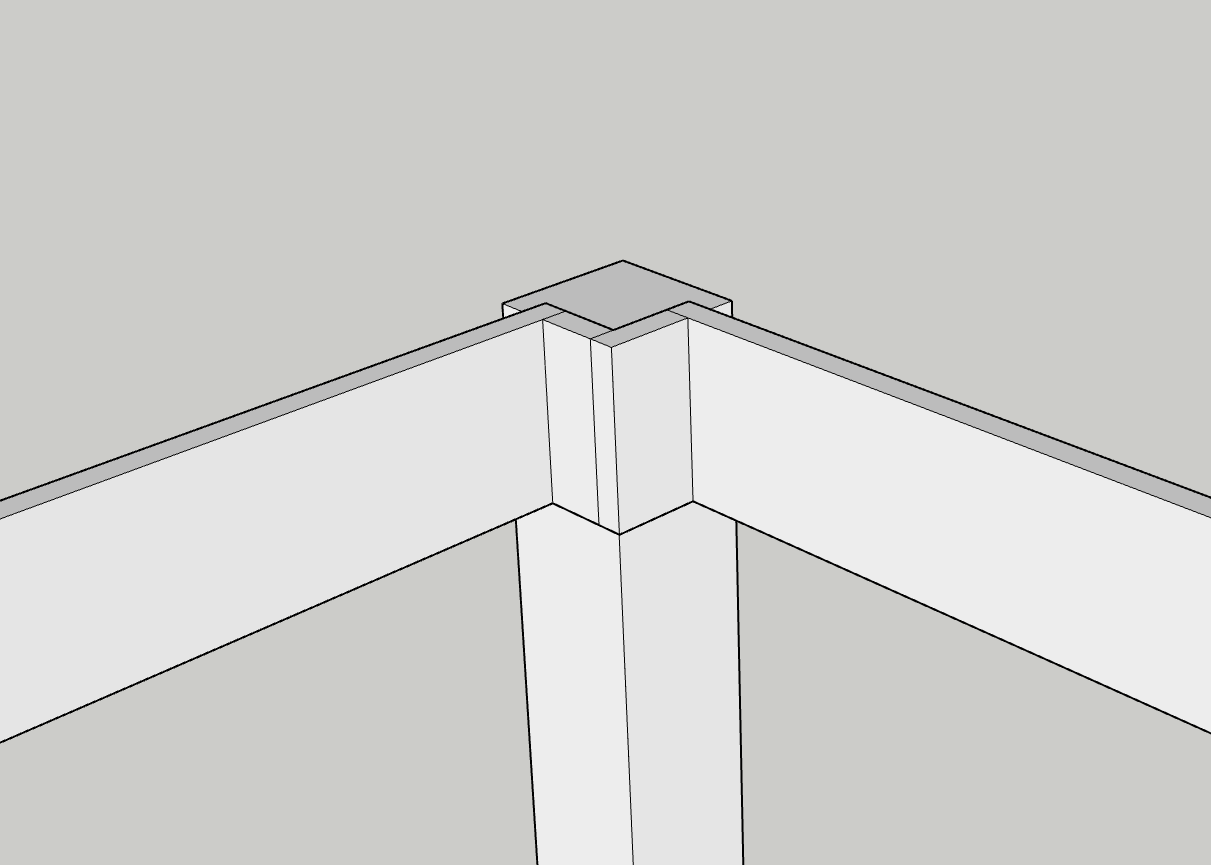

It’s not clear what you mean by “these pocket holes”, as your image doesn’t show anything that I would call a pocket hole. As you will read in @Royce’s reply, he presumes that you meant you want to create the pockets for pocket screw joinery. Is that what you meant?

The only thing akin to pocket holes are the two rectangular mortises that you faked by drawing small fillers adjacent to the aprons where they meet the legs. Is that what you meant?

I am assuming pocket hole joinery, how about making an oval at the location and labeling it as such?

For whom are you making this model? Presumably, since you are using the free web version, it’s for yourself. Knowing how to make a pocket hole for a screw in your model is a good thing. The idea can be applied to many other things. But before you make adding pocket holes a regular thing, consider the value they add to your model. Might be an ellipse tells you enough or maybe you don’t need to spend the time on that detail anyway.

Aren’t they usually made with a special drill and a jig? And preferably in as invisible places as possible.

Yes they are, usually. In some cases it can be useful to show them but most of the time I don’t think they add enough value to a SketchUp model to justify the work they take, especially if you have to do that manually like the OP would in SketchUp Free

Or you could download a component from 3D warehouse.

A few years ago I uploaded several sizes of Kreg pocket screws. And other people have too.

Mine were Dynamic Components so need Pro or Studio to customise. But others have plain components and should work in the free Web version.

Search the warehouse for Kreg pocket screws.

If the pocket holes are made using the Kreg system there are pre-determined measurements for setting the jig, the screw length, depth of hole drilled and most important the thickness of the materials to be joined. Best advice, tap Kreg pocket holes into your browser and you will find a plethora of info about pocket holes, jigs and size charts for everything involved with pocket holes.

All the best hope this helps you on your journey.

With SU pro you can use solid tools, create a “cutter” the shape of the Kreg step drill. position it and remove the material from the solid creating the pocket screw hole.

Hello i want to ask but not sure is for here but i try to make a place for magnet inside my object but after i put it in slicer is dissaper how to make a place aftef printer is print 2mm want to install magnet and keep printing

Wrong thread. You should start a new one.

Most likely though the face orientation of the hole is incorrect. Start a new thread and include the SketchUp model so we can see what you have done.