You do that… Okay!

Friday wasn’t such a good day. I was on the phone with my friend Bryant, who’s building the base, and noticed that an upper joint of one of the vertical pipes out of one condenser was failing. One of the challenges of drilling resin to add metal rod reinforcement is that it can weaken the resin that’s surrounds it. I think that’s what was happening in this case. I repaired it with epoxy while still on the phone.

I then put the TG deck and condensers onto my pull-out tray on the main workbench that is 90º to my movable bench. It was too close to the edge (apparently). My new desk chair is pretty big and tend to run into thing behind me when I swivel it. Usually it knocks over the trash receptacle behind me. NOT THIS TIME!. This time it knocked the entire TG assembly onto the floor. Thank goodness that all that was glued on were the condensers and the TGs themselves. IT BASICALLY WRECKED IT!

Enough of the support columns were whacked that I removed the rest of them. All that remained unscathed were the brass ones. So that’s the bad news.

In addition to the condensers themselves, there was some damage the foundation frame. I took care of it with Bondic.

There’s always a silver lining. In this case that optimistic view was my opportunity to improve the things that I didn’t like about what I have made originally. I had printed the entire condenser assembly as a single part which led to some significant compromises. I also didn’t like how the suspension frame came out. It wasn’t staight or parallel and I didn’t like it. Lastly, the resin columns were warping and weren’t responding to my attempts to straighten them. This catastrophe made it essential to fix these things. I keep saying, the biggest advantage of building custom with your own designed and 3D printed parts is the ability to make new ones.

I am substituting brass for all the columns like I did on the mezzanine decks. This neccessitated redesinging the condenser mounting frame to column interface. I had printed the frames with the columns. It seemed like a good ideaat the time to ensure alignment. Except the alignment was off. There were other aspects of the mount that were troublesome especially the cross-brace that tied the two sides together. It was too thin, broke and required a jerry-rigged doubling that looked awful, but no one would see it bured under the turbos. I didn’t like that either.

The new design has tubular structures that capture the columns. It’s not exactly as the ship does it, but it will be more effective with the materials I’m using.

The other changes dealt with designing the condenser itself for better printing. I separated the main parts and am printing them individually. The original had the interior of the solid structure hollowed out that required a large drain hole at the bottom. In this iteration, I’m printing the central part as a simple, open cylinder that will print much more easily, and the only surface details is the bolt circle one end that has no suports, ergo no damage to worry about. All of the parts having adjoinng sheelves to assist in assembly.

I need two and the first set just finished on the printer. 3 out of 4 parts were perfect. The end bell without the down pipe dlaminated between the bolt flange and the dome. It looks lke a drawing error where the parts were in actual contact. Meanwhile, I started the job again since the good parts will work and I’ll print the other as a separate job. It’s much lower and should print in less than two hours.

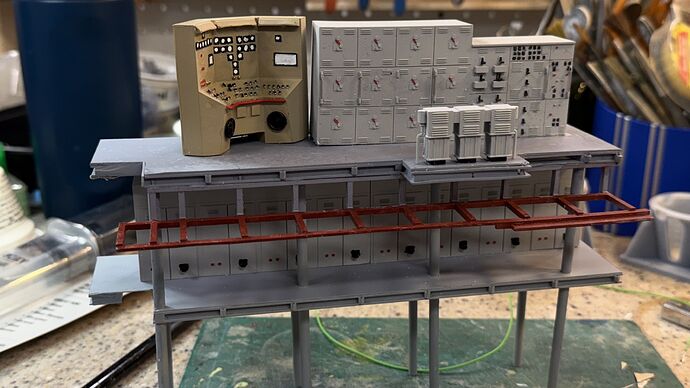

While the printing was progressing there was more to do. I almost finished building the mezzanine deck. I’m trying an experiment by using the 3M high strength transfer tape instead of glue. I did test with one of the extra cabinets and it seems pretty strong. Gosh I sure hope so. It makes the joint perfectly clean. After adhering the switch gear cabinets, drilled a hole for the control console wiring. I quickly found out that I could stuff all four wires down the 4mm brass tube so I soldered the ground from the console’s lighting to the ground connection from the other LEDs. It’s not a pretty joint and I may make a little junction box to hide it a bit.

The other end looks like this.

Here’s the mezzanine with cabinets permanently attached.

There’s a small angle iron frame at the base of the triple lighting transformes. I painted them off the model by sticking them to some Scotch Double-sided tape. I attach them tomorrow.

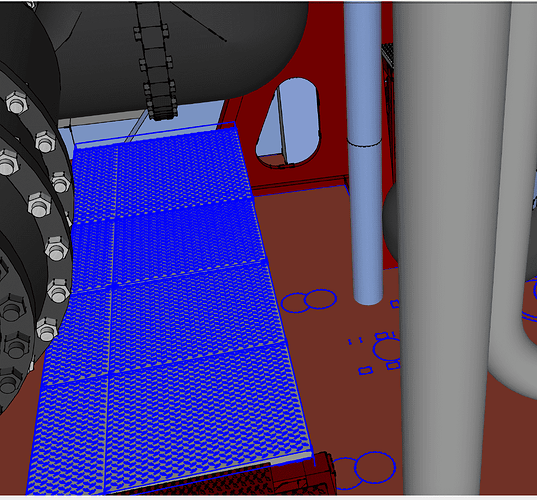

What remains on the mezzanine is the railings and floor gratings plus some more touch up painting.

While I’m waiting for all the replacement turbo gen parts, I will keep moving through those things that I can assemble. Next up will be the evaporator decks. I have to get the vinyl cutter working. I want to make some of the graphics that way. Oh… I might have found a vendor to produce some 1:48 sailors in proper engine room dress. He’s from Greece and I saw his stuff on eBay and Etsy. If it works out, I will publish his information.