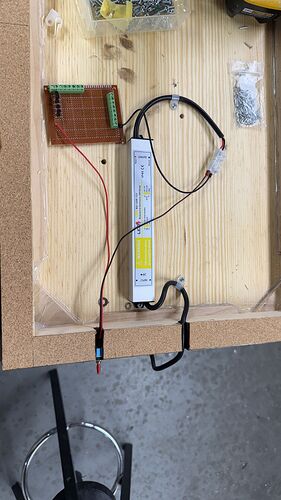

This post covers two days. Yesterday, I finalized attaching ALL the electrical components below the base. What’s left will be the very last task performed, after the case is built and mounted, when I turn it on its side and attach all the field LED leads to the circuit board. It’s AFTER the case is on to protect turning the model on its side.

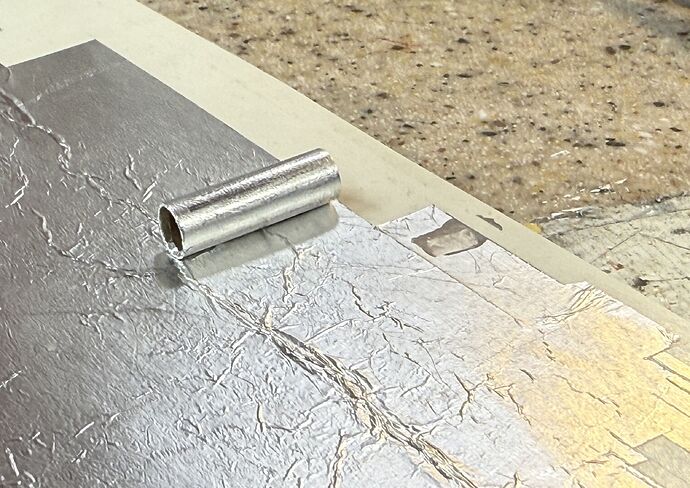

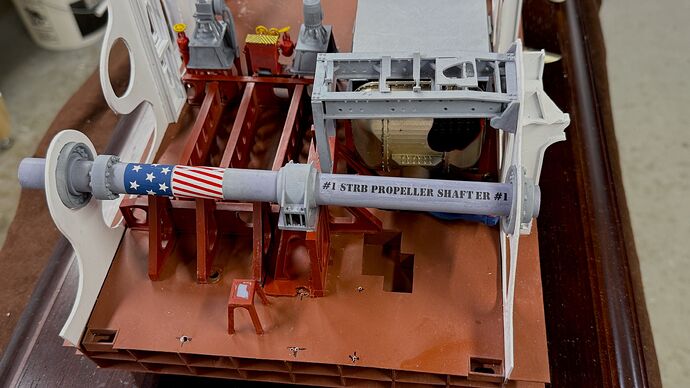

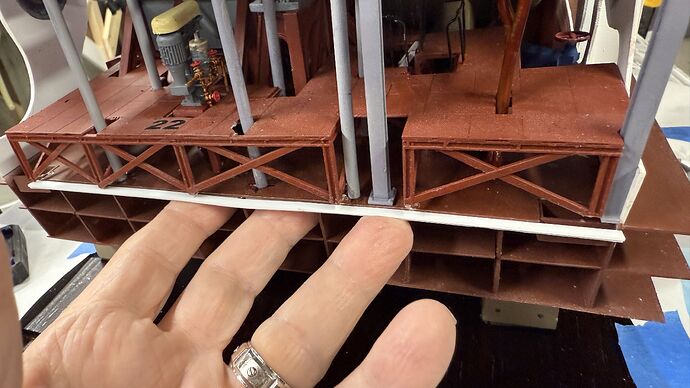

I flipped the base over and got ready to permanently affix the model to the base. Flipping the bare model on its side, I peeled the backing film off the double-sided, foam servo tape. This stuff holds like crazy and, unfortunately, holds its backing film with equal force. This image represents almost an hour’s effort. A couple of the faux dry dock blocks popped off due to all the manhandling and had to be reattached. Slowly, I started to get a bit better at getting the backing off without either pulling off the foam tape or breaking off the blocks.

Once all were open, I carefully held the model against the masked lines and pressed the model onto the base. I was rewarded with an extremely firm adhesion. I could probably lift the entire base by pulling up the model, but resisted the temptation for fear of catastrophe if I was wrong. Each block may not be that strong, but 24 of them have a lot of collective power.

I’m glad I chose to go with the dry dock blocks. It made it more understandable (to me) on how to fasten the model to the base.

Today I went to General Rubber & Plastics to pick up the cut Plexiglass. It was supposed to be cut next week, but they were early and I’m happy. Monday, my good model buddy, Chris Bowling, is coming over to lend a hand, and having a master builder like him around to help with the case glue up is great. All the pieces look like they fit pefectly. When you’re in a model contest where Chris has an entry, the best you can do is 2nd.

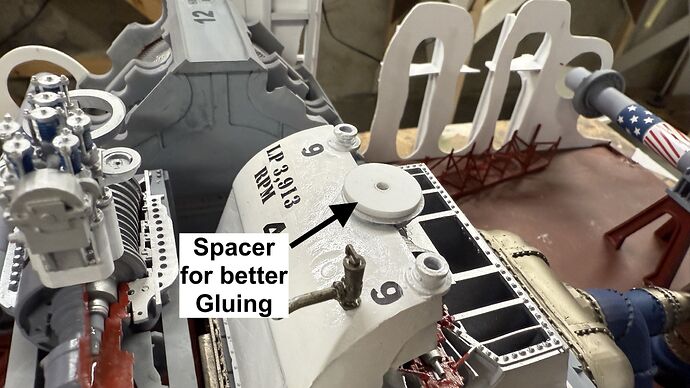

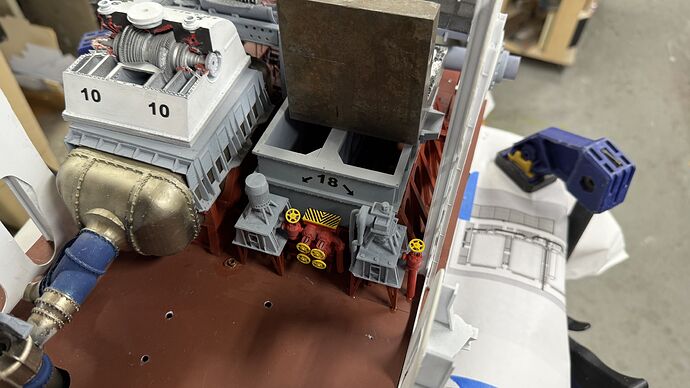

Back in the shop for a short session, I added some horsepower decals to the model. Having the RPM numbers without the horsepower numbers seemed incomplete. I also added the latest RPM decal to the repainted MRG top.

There’s not enough clear space on the HP turbine itself, so I put the decal adjacent to it.

i still have to add a new number “12”, which will happen on Monday after the decal is fully set.

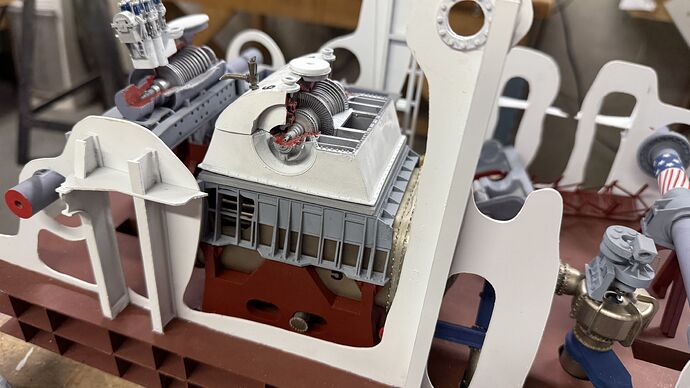

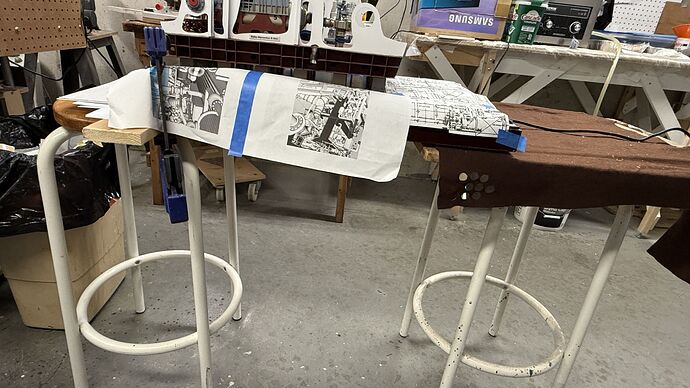

Now to the next very challenging task. Arranging and marking the location of all the units and their mounting pins. I’ve chosen to do this by re-using the floor template sheets. I added the holes for the main condenser piping and will situate all the units in their exact final locations. First thing was setting up some 3º guidelines to ensure that the MRG/HP and main condensers are all rotated on that bias. Then I laid on the TG unit AND the work platform that spans the gap between them. This platform (and others) are critical in spacing out many of the unit positions on the model. I got it in position where it looked right. I couldn’t nest it into the I-beam TG frame because the TG is proud of the surface by the height of the mounting pins. They will be sunk in holes when in final position. This entire exercise is to locate those pin holes.

I had to trim the lenght of the big lube oil filter’s piping since it was restricting my ability to move the TG unit fore and aft for final positioning. Their length was just an approximation anyway. I don’t really know where the pipes go on the ship. They’re under the floor plates.

So… the task is to locat these kind of things on the template, make holes in the template and then spot them on the actual floor. I chose to do it this to keep as much damage off the real floor as possible. To complicate things I’ve created two different kinds of mountings. Oh well.

Monday will be taken up with building the show case, and further work on equipment locationing.

Everyone have a nice weekend. Weather here in Louisville will be spectacular. Tomorrow is my model club’s annual judged exposition. Our club, the Military Modelers Club of Lousiville, is celebrating its 50th anniversay and the two founders are still members. One, Brian Bunger, is the propietor of one of the best hobby shops in the USA, Scale Reproductions, Inc. He’s an avid and masterful model builder himself and the shop reflects his love of the hobby. The club has many fabulous builders and I’m very proud to be in their company.