Wood Threads.skp (45.6 KB)

Using native tools in Go, what is the best way to go about cutting/extruding the threads. I have a 2 1/4" holesaw bit and after drilling a hole I want to make Vee cut threads. I modeled a hole drilled into a 4"x4"x2" block at 2 1/4". I then made a tube of 2 3/8" diameter and made spirals with a 3 degree angle. I looked at some videos but did not find a way to do this. I tried follow me. When I did manage to extrude, it did not line up correctly around the tube. Once I get a Vee cut made in the spirals, I was thinking to intersect faces to cut the threads in the nut.

Follow Me won’t work for this even on the desktop version of SketchUp. What is the pitch of the threads supposed to be?

I made the spiral at 3 degrees. I didn’t figure anything else out. 3 degrees looked about right for a big wooden nut and bolt.

How many thread per inch do you want?

About two or two to three.

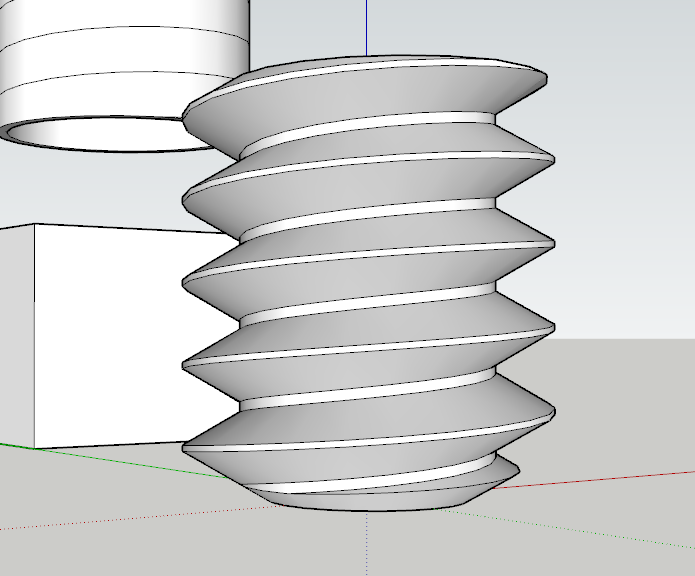

First, it would be smarter to work centered on the origin so you have that as a reference. Here I’ve included a circle for reference although it isn’t required to model the threads.

You could start by drawing the cross section of the thread. Put in the correct angles and allow for the widths of the flats in the valley and on the crest. Use Rotate/Copy to copy those edges to the nest vertex on the circle and then connect the edges to get faces. Raise the right hand end edges up the required distance. In this case you want one turn in one half inch (2TPI) and I’m using a 24-sided circle so I raised the edges up by 1/48 in. I made that geometry a component to make it easier to handle for subsequent steps.

Then Rotate/Copy the component to make the next sector and move it up by 1/48 in.

You can select the pair and copy them to make a total of 4 and then rotate/copy them to make 8 and keep going until you have enough to go around the circle once. Move the components up so they align with each other.

Use Move/Copy to make as many turns as you need. Explode the components and soften the edges.

You’ll probably need to make a few more turns than you actually need so you can cut the ends off flat with intersected faces.

Great. I will do this. Thanks Dave,R.

FWIW, once you have the screw as a solid object you can use the Trim tool in the Solid Tools to cut the threads in the block.

Will do.