Yep, do something similar… most of my sets are less than 40 pages and the revision list is seen on all pages with the revision code unique … the publish (issue) date is always shown on every page and the pdf file is always preceded with the same publish date in YYMMDD format…

Most of my sets are Concept or “Design Intent” phases so revisions are minimal

Yes, I was beginning to explore this way of doing things. I was slowed down by the fact that I use a Mac and do not have a fully fledged version of Excel. It seems you can’t do the same thing with Numbers. But maybe I just have to bite the bullet and shell out for a second spreadsheet software.

You say

But later on you say

So I am not quite clear whether the automation you suggest is currently possible or not. You would certainly want it automated if possible as it both saves time and potential for transcription error.

As someone who’s been on the receiving end of continually revised sheets, every change to any sheet should cause a reissue of all sheets and the should all have same current revision and date designation. Otherwise you end up with a confusing array of sheets issued with different revision codes and not knowing if some may be outdated.

Given that most subs are now working with pdf’s on a tablet rather than actual paper sheets, it’s not a costly way to do it. Ya, I can dream about that all plans on tablets future, can’t I?

On the offshore cable company I worked, the filing system was simply a 3 letter project prefix followed by date, hour, minutes for the document, Docx, Dwg, SKP etc.

We could always find the last (or previous) versions by simple file search.

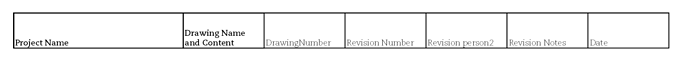

So I made a Drawing Register in Excel, and can reference a single cell or row from that table onto a sheet within a LayOut document…pretty standard stuff.

What I wasn’t 100% sure about is how the update between Excel and LayOut works.

But I did some testing this morning and I can confirm that a change made in Excel will update the referenced table in LayOut automatically. This chang will be visible when a PDF is exported, even if you don’t click into each LayOut sheet or manually “Update Reference” on each table…that’s what I was afraid of needing to do.

Hope that clarified things.

My system is based on the way i used to work on tracing paper, then microstation, and now sketchup/layout…

i have a layout file for each drawing, (1 for plans, for elevations, sections ect… but not using LO pages at all).

the models are called 00e (for existing) and 00p (for proposed).

When the model has to be changed and issued, i open the model file,

SaveAs YYYYMMDD-00p, then reopen 00p change it, and then open each Layout file, change the revision number and issue it.

So i have an archive of the model files in case i need to go back to them, and when i issue a drawing from layout it goes as a PDF file, where the file name includes the revision number so i have an archive of each issue in pdf format.

I’ve never felt the need to save different Layout files for each revision, in my head its just a piece of paper!

I like the idea of this – it’s revision by project not sheet…?

So how do you do this?

You’ve issued a project set of documents at, say, Revision A – First Issue.

You need to make changes to some of the documents and issue the entire set of documents at Revision B…?

Even if the builder is ok with PDFs they may have printed out the Revision A set – when they get the Revision B set they probably will only want to print out the changed drawings.

So you could end up with a situation where the builder has a collection of paper documents with different revision designations.

As long as there is a clear record of what you have issued then any confusion that might arise out of a builder just printing out changed documents is down to them…?

These are subjects near and dear to my heart…

The truth is, the niche of the industry I’m in, design and building of custom homes, is so far behind the times technologically that it’s really an embarrassment at this point - or should be to everyone. I read an excerpt from, I think, a McKinsey report from a few years back that noted in the past 20 years or so (probably paraphrasing badly), every other non farm industry has leveraged technological advances and capabilities to increase productivity by 200%. In that same time frame, construction productivity has actually declined.

“We’re in construction and we don’t need no stinking badges!”

The situation you note, Paul, is precisely why the printed plan has to just disappear. Full stop. Electronic plans will be alway updated automatically and no one can make the mistake of referring to the wrong, out dated set. It’s such a simple idea a child would understand - but builder? Nah.

How you would number revisions, I’m not sure but I would think, conceptually, a major / minor revision tracking schema. What would trigger minor to major, I’m not sure of, perhaps # of sheets that are changing.

And, yes, every revision would need its listing of what it is that has been revised. The software industry seems to have implemented this fairly well.

We’re well into the 21st Century.It’s time for the AEC industry to leave the 8th Century behind.

You may enjoy this video I put together awhile back (Dropbox link):

In this case, I’d start with a template with a whole bunch of “on every layer” revision letter layers. It could get really cluttered in the layer palette but if not going through the entire alphabet it wouldn’t be unmanageable. Then, if the template starts with all of their visibilities toggled off, you only have to toggle on the A layer on the page when the first rev occurs; the on the second rev to the same page, toggle off the A layer and toggle on the B. It’s more of a work-around, not an automation, but it seems like it would complementary to the spreadsheet.

So you think that, for example, a bricklayer should carry a tablet next to the hammer and trowel in a tool bag and check every day if something has changed?

yes, I do. I’m sure they’re checking their phones all day

If the bricklayer is a sole contractor contracted to undertake some work on the project or is responsible for a small team, then actually yes, (these days) they should be receiving relevant construction documentation digitally and be responsible for making sure that they have correct up-to-date documentation.

If they want to print out for the day or weeks work for themselves or their team, then that’s up to them or they may indeed keep some appropriate device with them in their Otterbox case or close by in their van perhaps.

I agree with above

But this:

it’s complete nonsense. Try to find a carpenter to build the house by giving him a building documentation CD and a contract with the point that he is responsible to look for an update. Imagine a situation where one day a designer will make changes (which will be expensive and unnecessary), and after a few days he will undo it without leaving a trace of them. Who will be responsible for it? The contractor is to receive documentation that is approved by the investor or an authorized person. Experience shows that success have many fathers, but no one is willing to admit a mistake

Disagree with you.

I was once a full time contractor and I made it my business to know that I had up to date documents.

I am on a project, and there have been 27 revisions. The engineer gives the revised set a new number, and changes are noted and bubbled on that revision, The next revision, has the former bubbles (clouds) removed and new bubbles and notes are added, where new changes have been made.These are autocad plans, but it makes a certain amount of sense.

They are distributed via PDFs and the subs are free to print hard copies if they wish. The concrete sub had his on a tablet. I preferred paper plans.

G

I basically send a pdf of the all drawings drawings including latest versions each time. I give the pdf a version number and that means I don’t have to trawl through a version doc for each sheet.

The guys only have to check which pages have changed which is each made clear by their revision numbers and dates. From their point of view it’s a single PDF and easier to swap out with earlier versions.

I think this is the new method I am going to try.

It’s interesting that some here think builders should move into the 21st century and stop relying on paper drawings. Of course it’s true that everyone at least has a smartphone these days and so interrogating plans and models on screen using their ability to zoom in and out should render paper drawings obsolete. However, that is easy for someone working in an office with computers all day to say. Out there in the real world, I have yet to come across a builder, let alone a subcontractor, who would willingly do without paper drawings. My own experience is that getting away from paper and from traditional 2D plans, elevations, and sections, is still quite a way off. Just like offsite construction which arguably ought to be standard but still seems miles away here in the UK.

If, as a contractor, someone offered me an attractive payment for doing something, but on the condition that I had to take care of updating the documentation myself, he would thank me and refuse to accept such an order. Because imagine that at At 12.00 you start to put up the wall, and at 12.05 a fix appears on the server. Or the CNC machine tool starts machining and 5 minutes later a correction appears.

This is a perfect video! I love “constructing” but getting the ever more complex structures down to a 2D plan in order for it to look “like it always did” is extremely cumbersome and error-prone. We are working hard on enabling our employees to simply open Sketchup-Models to take measures and check for details - combined with some VERY general assembly plans and some VERY specific details that would be hard to catch in 3D…

If you fall for that, most likely, you will run into other problems as well. There’s nothing wrong with making agreements and having conditional terms when engaging in the real world.

Even in the designing phase, one should make or at least have some kind of contract of what to deliver to the client (hourly based, level of detail, etc)

It’s true that one might not be comfortable with the ‘BIM’ way of working or the shift that is currently happening in the AEC industry like changing responsibilities, multiple stakeholders, virtual building, etc., but any reasonable project initiator should have a working method/process and working agreement for its stakeholders.

So if you make a quote based on drawing X, revision C and it is now revision D, it’s your responsibility to update the quote or have a clausule in it that takes care of it.

In these days, even when there are no revisions at all in a project, one could face increasing prices of lumber or other suppliers, so it is important to deal with that, too and have the most updated data all the time.