i could post a real model with the issue if you want to try it and see what i am talking about.

dennis

Texture has nothing to do with it. It has to do with the direction of the normals. I’m not just pulling that out of my hat. Besides, leaving faces reversed is just sloppy modeling.

Go ahead and post it. It would have been helpful to know that the file you posted wasn’t the actual model.

we have been having this issue for months and i decided to try to figure it out. i will get a model ready that demonstrates the issue and post it.

thanks

dennis

here is a model with correct face orientation that looks fine in sketchup - there is a small hole in the front. the .stl file looks ok in meshlab. when i get the shapeways visual render (and the part eventually) the hole in the front has “healed”.

this is a sample of the problem we encounter almost daily.

this happens with holes of all sizes but it’s always concentric holes (same center) that are involved.

dennis

test.skp (452.4 KB)test.stl (335.7 KB)

Hi @timmy,

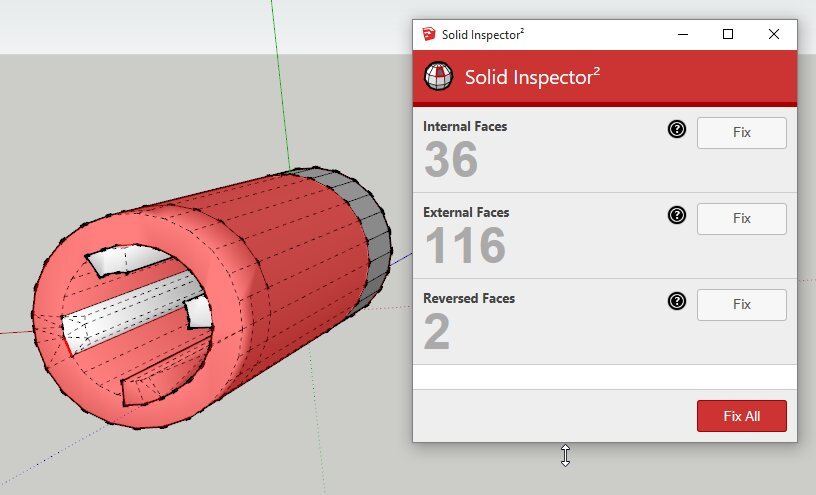

I had a quick look at your part and the first thing I noticed is that it is not solid, which is a requirement for 3d printing to occur successfully.

ThomThom’s SolidInspector 2 extension will help you validate if your part is solid and report errors when it finds them.

As per what I saw when hiding a few faces here and there, redrawing your part properly might be a faster solution than trying to fix it:

Not all the faces have correct orientation. I changed the face color to red so it’s more obvious.

There are a number of internal faces which aren’t allowed as well as some missing faces. I hid one of the outer faces and so you can see an internal face in white and a hole.

I’m curious as to how you are drawing this thing. From looking at the hidden geometry which shows a lot of excess lines, the reversed faces, holes, I have to believe you’re working harder than you really need to.

It’s NOT a solid when made into a group.

It is no fixable using this tool or my SolidSolver tool…

Look at the highlighted issues and manually correct them…

thanks. i see those open faces inside and i am sure that’s what caused this hole to heal. one thing i don’t quite understand is that sketchup never tells me it’s a solid group. i use solid inspector but i have never tried solid solver. i understand solid inspector can’t fix everything and i make changes until it does the best it can. i will try sold solver - where is that available? i totally agree this model is a “mess” - most of our models are much cleaner and i just grabbed one that we were fighting with yesterday.

dennis

i think i fixed all the issues you identified and shapeways still closes the little hole?

dennis

test.skp (154.0 KB)test.stl (340.4 KB)

ok i ran solid inspector and it is now error free - but it ate half my model?

dennis

This is painful. Do you have some sort of dimensioned drawing or sketch you’re working from? I’ll draw it for you so you can see how to do it without creating all these problems.

no dimensioned drawing. i really am not as stupid as you might think. i am an engineer and have draftman skills. i am just missing something here - i cannot see what solid inspector is complaining about? i didn’t do the drawing we are working with - a trainee did and i hadn’t really looked at it. i don’t see what is wrong with the back end. i removed the smoothing he had applied and looked at all the faces and they seem oriented right to me?

dennis

ps. yes this is painful

I don’t think you’re stupid but this going back and forth isn’t making any progress and it’s wasting the time of a number of people including you. The truth is, the model is poorly drawn. I’ll make a clean one for you but I’ll have to pick apart the model we’ve got. I suspect the dimensions in it aren’t accurate.

you don’t have to do that. let me try applying the stuff i picked up today about where i might have gone wrong and see if that helps. other than the hole healing issue with shapeways i haven’t really had any serious issues with 3d printing using my own printer or with shapeways…

dennis

ps. i totally agree with you that this model is a MESS

Well, I’m almost finished but I need to know about the splines down the inside. Are they all supposed to be the same shape and are they supposed to be symmetrical.

I really don’t think trying to fix the mess is worth the time it’ll take. It would be much better to redraw it from scratch.

they are symetrical guides and should all be the same shape.

When you manage to make s non-solid group then it’s easy enough to stop it being fixable in code.

Convoluted geometry is hard to resolve.

But your brain CAN fix it…

Use a combination of Xray mode to see inside it, SectionPlanes to access the interior and drawing lines over existing holes’ edges to make missing faces infill, and erase unwanted flaps and internal-partitions etc and any unfaced edges.

Once it is a solid the faces should be oriented so you see NO ‘back-face-material’.

It’s possible to make a seemingly ‘solid’ object that can’t be printed.

For example where part of the form penetrates with the rest of it, without intersecting.

Once you have a ‘solid’ reported in Entity Info, edit it and select all of its geometry, use the context-menu Intersect with Selection…

Exit the edit - if it says it’s no longer a solid you have some more work to do on fixing issues…

Remember that a ‘solid’ can only be a group or component-instance which consists of only faces and edges, and every edge must support exactly two faces - so that means no faceless edges, no holes where an edge has only one face, no flaps or shelves where at least one edge has just one face, no internal partition-faces where an edge has three or more faces etc…

i will study your replay and do my best to follow your instructions. i already do most of what you suggest and just didn’t do it with this model. when i have an internal void in my model with no openings to the outside surface should it appear to me as as an outside surface when i navigate into the void and look at it from there…?

dennis