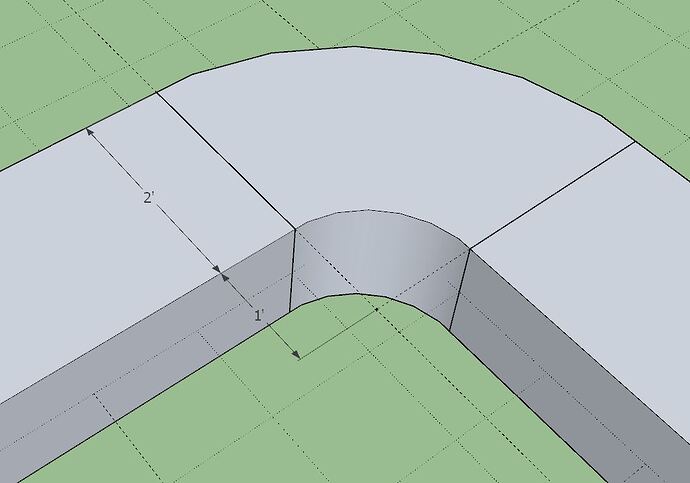

Currently the bend radius or centerline radius is hard coded into the plugin, I will need to make this user configurable, my apologies for forgetting to do that with the initial release. I always forget something.

Specifications can be attached to the component objects using an AttributeDictionary. (Either unique to the extension, or the OEM dictionaries SU_DefinitionSet and SU_InstanceSet. The latter may be accessible in Generate Report and LayOut.)

External data can be kept in JSON format that is easily read by Ruby into a Hash or more likely an Array of hashes, each being the specifications for a specific model item. The keys could be the model numbers. You could keep the OEM items each in their own file, or have one file with a hash whose keys are OEMs, whose value is an array of hashes for each model, etc.

Ultimately the actual data for the device will be stored in an attribute library that the user can then edit as they see fit, but the initial values (from the manufacturer) will probably just be stored in a flat text file (CSV) or a JSON formatted file. I will work out the details at some future date, either way it shouldn’t be to hard to manage.

My main point is that all of this data is available from the manufacturers and can easily be incorporated into the extension which encourages me to think that I can probably implement some actual calcs into this plugin. Perusing Manual D this morning and my first thought is that there is actually quite a bit to these calculations, I do have my studying cut out for me.

What a legend.

THAT is the key…

Something else to consider:

Version 0.9.1 - 07.29.2025

- Updated the draw and edit menus for HVAC appliances.

- Added the following brands and associated models into the HVAC appliance built-in library: Bryant, Rheem

It seems like you could tackle a piping/plumbing extension pretty easily after this HVAC one.

That is kind of the idea, hone my skills and ideas with the HVAC plugin and then use this code base as the starting point of the plumbing plugin. However the algorithm is going to be slightly different, I’ve already determined that.

I haven’t received very much feedback yet with this plugin so I really don’t know what works and what doesn’t at this point. What feels klunky, what feels right.

I’m not sure how it works in the US, but in Europe, architectural and MEP modelers are different roles. Therefore, if the users of your extensions only work on architectural modeling, they will likely find that type of modeling less relevant.

The users of my extensions are actually quite diverse. Obviously many of the users of the Electrical plugin are more interested in modeling electrical fixtures and wiring and so one would expect them to be electrical contractors etc… I really have no control over who decides to use my extensions and I also don’t have exact numbers or percentages of who those users actually are. All I know is that it is a mix of contractors, designers, architects, wall panel manufacturers and of course DIYers.

The feedback and installations are starting to trickle in but I need more data…

Even though this extension is very much in BETA stage and still needs a considerable amount of work and more assets added I have decided to allow the purchase of it at a reduced price for those early bird users who are already finding it useful.

You can currently purchase it at 1/3 the price, which should make it very reasonable even though it is a work in progress.

Additionally with more invested users I will obtain more feedback and suggestions which will help me further iron out bugs and add more value.

I have never seen that used on a job. Maybe on dust collection systems? But never on a AC system. BUT? I have been wrong before at least once…![]()

Hey sorry @medeek , I have been super swamped because this is the season all the HVAC guys get swamped. I am working on a rigid duct detail drawing so you can understand what lengths of duct are possible for rigid ducting, with different types of termination fittings since that will vary. My hope is that we can use your extension as a true BIM so we might have a true material list take off which would save countless hours.

Then I will work on the “riser boxes and riser pipe” which are fairly common as well.

I will try to download the extension tonight. I hope the libraries I sent over are helping you develop this extension.

I still have a lot more modeling to do as far as assets and fittings, I’ve only just begun.

Right, it didn’t say specifically AC use. So I wonder what it is aimed at? Perhaps marine uses? Perhaps air circulation in mines (fresh air input or dust exhaust) ? Like you say, perhaps other industrial dust collection (sawmills, flour mills, grain elevators, etc.)

I would wonder if the PVC meets fire code standards for building use.

When I first started my business back in 1998, all I did was ultra high end homes in the Palm Springs area. And all that duct work was underground due to the extreme changes in elevations and the vaulted ceilings. There was simply no attic and even if there was, there was no way to get the ducting from point “A” to point “B”. And the amount of glazing was astronomical. Those rich people would build a house of glass if the state let them. So all the ducting had to be underground PVS (Poly Vinyl Spiral) ducting. And any 90’s, T-wyes, sound traps or register boxes all had to be encased in concrete. The PVS did not because it had a cross sectional strength of 2000 lbs. per linear foot. But anything that was galvanized had to be encased in at least 4” to 6” of concrete. It was specialty work and I was one of the few who could design it, install it and get it done correctly. Those were the days…sigh.

Anyways I know that back in that day, circa 2003 or 2004, there was a wave of suppliers that started selling us PVC pipe for underground ducting systems. I was out of the game by then. But the pitch was that PVC pipe did not need to be encased in concrete. We still did the register boxes and sound traps but saved a bunch on concrete and labor. And then the state came in and dropped the hammer after about a year and it all went away.

I guess my point is that I believe you are correct and that PVC cannot be used as a air delivery product in HVAC systems. Probably for the same reason you are not allowed to have and coated wiring in the air stream unless it is “plenum rated”. Add to that, the insulation needed to meet Title 24 requirements (Or whatever energy code you fall under because I am not totally sure Title 24 is just a California thing).

Oh this does remind me that a lot of general development CBS homes here in Florida use foil-coated fiberglass board for ducting. I don’t think I’ve seen it in commercial builds though.

I think I have also seen the round flexible foil over fiberglass ducting that has a spiral wire inside to help keep shape.

Thermaflex® M-KE Flexible Insulated Acoustical Air Duct | Thermaflex

From a home owner standpoint does duct cleaning do all that much? Is it worth it?

Quite a few years ago my furnace guy was trying to sell me on it.

To help with the uptake of this new plugin I will running a promotion for the month of August and September (Aug. 10, 2025 - Sep. 30, 205). If you purchase the mdkBIM bundle both the Medeek HVAC and Medeek Electrical licenses will be included at no additional charge ($120.00 value). Each of those licenses will also be permanent licenses.

However this is not automatic, you must email me within 30 days after purchasing the mdkBIM bundle requesting the two additional licenses and I will then issue them manually. They then will become accessible with the Medeek Account Manager the same as your other licenses.

I am only posting this notification on the SketchUp forum and the Sketchucation board.