I have spent days building and perfecting my workbench design. Now that I am collecting my materials I need to make some adjustments to the dimensions. The project is mostly plywood and I designed the model using 3/4, 1/2, and 1/4 inch material in mind. Well plywood is not exactly those dimensions and now I would like to change the entire model with the real dimensions. Otherwise my material will not line up properly after it is cut. Is there a way to change all dimensions that are 3/4 or .75 in sketchup pro to 11/16ths? Thank you!

Not automatically. But if (as I hope) you made your model with components, it should be quick to use pushpull or move tool to change the size of the pieces, and the dimensions should update.

Upload your model to get more detailed responses and help.

Depending on how you modeled it, changes may be easy to make although it won’t be a one step thing. It may not be worth the time to make the changes. Is your plywood truly 11/16 in. thick? A lot of plywood these days comes in metric thicknesses.

I would point out that it isn’t necessarily obvious what else needs to be adjusted when you change the thickness of your plywood. For example, if you are making a cabinet 36" tall I would think you would want it to stay that size regardless of what thickness plywood you use. So, you will likely need to increase the length or width of parts to make them fit against the decreased thickness of others while maintaining the same exterior dimensions.

As the other have said, if the model uses components appropriately that will simplify things a lot but there will still be some manual tweaking needed. That said, unless your design is quite complicated, it really shouldn’t be all that much work to fix it.

wow, thank you for all the fast responses. Everything is in components, it is just a lot of pieces that need to be adjusted and moved slightly. So I was hoping for an easier way than push/pull.

Nope. Sorry. As @slbaumgartner says, you need to apply manual judgment. But if the model is well constructed, it should take only a few minutes to fix.

If you find it’s taking longer, upload the model to get further help and advice. Both DaveR and Steve are expert woodworkers, and I’m an interested amateur, so you’ll get the benefit not only of SU advice, but that of workbench users too.

Try not to change the component origins, if they are already at a corner of a piece of the bench (and if they aren’t, put them there).

Move or pushpull at some non-origin face. Then if you generate a parts list using Generate Report, you won’t get the wrong dimensions (which are of the component bounding box).

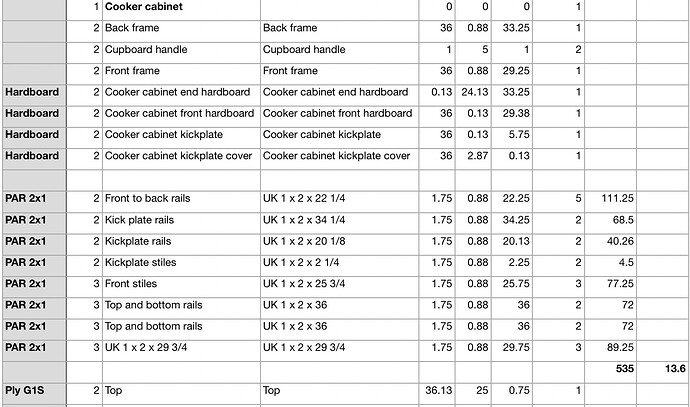

I’ve just done (for the first serious time) a report for a theatre set design for the play Skylight, using Generate Report to get a parts list for three models of kitchen cabinet (for on-stage use only - these aren’t practical cabinets), grouped by Material, Entity Name and Definition name, and displaying X, Y and Z dimensions, and quantity, for each component in each cabinet.

Here’s one of the cabinets, and the Generate Report output copied and pasted into a spreadsheet to sum the lengths of pieces of 2x1 softwood, convert to metres and estimate the cost.

Skylight - Cooker cabinet detail~.skp (874.8 KB) !

Skylight - Kitchen cabinet cutting list.xls.zip (6.4 KB)

Incidentally, the framing was all drawn using Steve’s and my Wood Framing extension from SketchUcation plugin store. That’s where the sizes in Component Definition come from.

And I see I forgot to give one of the components an Instance name.

I would routinely measure the plywood we got in for each project because of inherent variance in the product. I found it useful to stack four sheets and measure at different spots for thickness with calipers, average them out, then divide by four for as close to normalized measurement as possible (in thousandths). It’s a little more critical if you’re loading a CNC program with that data, not nearly as much with a manual build, but still helpful.

Chasing the inherent thickness differences across sheets of plywood and trying to model that in SketchUp would be a huge waste of time even for CNC work.

It wasn’t for SketchUp. Cabinet Vision. And all you had to do was update the information for a set material, and everything updated globally. Super fast and easy. Kept joints from being sloppy, and cost me about 15 min for each run of cabinets. And this was only for every bunk of plywood we got in, not every sheet.

And I now realize it was kind of pointless to bring this up here, sorry.