Thanks for the input. I’m using the acrylic adhesive that they sell at the plastics house. It appears to work like other acrylic cements with very low viscosity and the ability to be attracted by static charge.

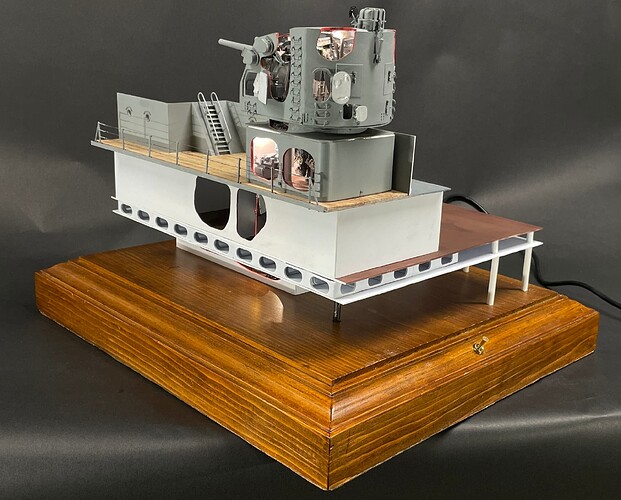

The replacements were available today. I picked them up in the early afternoon and got the case built by 4:30. I’m getting better at building these things, but I’m still not great. This one has a minimum of glue where it’s not supposed to go. For that I am thankful.

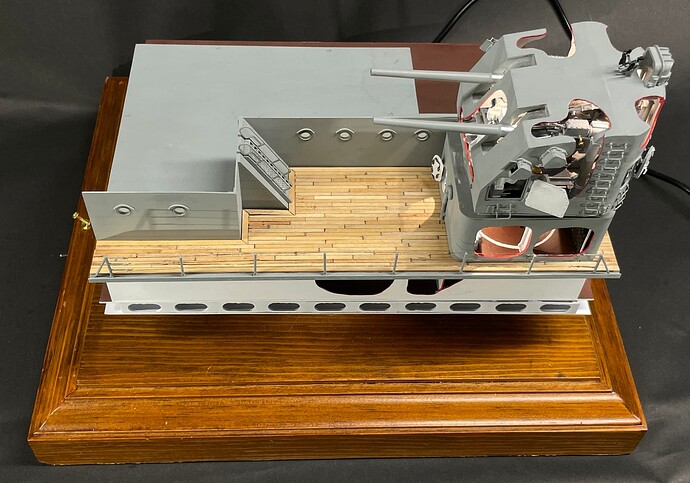

Before I retrieved it, I did more detail work on the model. I installed 3/16" square stock edge thickeners on the upper superstructure to provide more glue surface when I glue it down tomorrow. I also added a corner brace to square up that external 90º corner. I then started to paint it and realized I hadn’t installed the “eyebrows” over the portholes. It’s a little detail, but I wanted to include it. I was using a very forgiving paint (Life Color), wiped it off and made the eyebrows out some very small styrene strip. I got them on and painted the part. To fully cure it takes overnight.

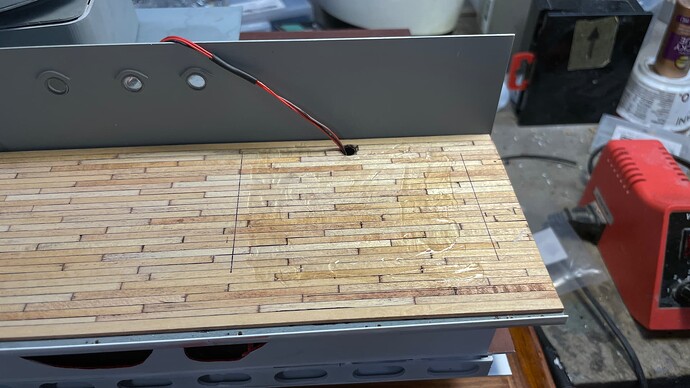

I also finally painted all the cutaway edges of the magazine and 2nd Deck compartment openings, and final touch up on the gun house and UHR. They’re all ready for final assembly. I used Vallejo Crimson Red, and then back painted all the red that got on the outer surfaces with Vallejo White. Both paints have good hiding qualities and the final looks very neat and trim. I’m still worried about doing the planked deck. It could take a lot of time which I no longer have. I have two days!

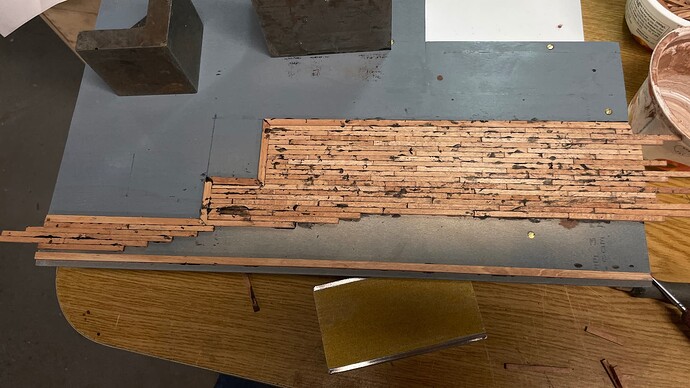

Then I got the case parts. I was disappointed that the replacement parts were saw-cut and not CNC milled. They were much rougher and had some chipping. I’m not complaining. They turned the job over in less than two days. They’ll suffice.

To clean up the edges some… I have a edge sanding contraption that I built when gluing up balsa skins making a very large RC aircraft 13 years ago. It’s a 1X3 screwed to a 1X4 capturing the sandpaper in between. It provides a long, square edged surface with abrasive and works pretty well. The saw marks were deeper than it was reasonable to expect their removal via hand sanding.

After cleaning up the edges as good as I could get, I determined the edge that were going to get glued and created a very slight chamfer on the inside glue edge with a sanding block. The chamfer is very small, but enough to help guide the needle applicator and promote capilary flow. Speaking of capilary flow, I was also told to use a Q-tip and coat the glue edges with cement before taping together. It helps flow into the joint.

The fellow at the plastics house also recommended removing ALL the protective film. It just gets in the way. Acrylic has a lot of static charge. It’s a problem because it will draw cement off the applicator and deposit it where you don’t want it. Another trick he told me last time was to do all the work with the assembly sitting on a damp towel to reduce static charge.

I then used two micro-fiber cloths to clean off any dirt and sanding debris. One was damp followed by a clean dry one. These cloths are fabulous! I bought a stack of 100 of them from Amazon for something around $12.00. They’re washable and worked great on the stove, cleaning leather car upholstery, mirrors, etc. And they worked great on acrylic!

I started taping it all together using Tamiya wide tape, but it didn’t have enough grip strength to hold it together. I switched to 3M Blue Tape. I put the sides together first sitting on the top piece, and then errored thinking that I had to turn it over to get the top fitted. That attempt loosened a lot of the tape forcing me to reconsider. I replaced the taped-together-walls back on the top, slide it off the table a bit and so I could apply tape to its underside, rotated it off the edge and did the rest of the sides in order.

Tomorrow starts the full-court press. If I don’t get it done, I can’t blame the Plexiglass.

I applied the glue using the last tip I received; squeeze the air out of the bottle applicator and then release as you rotate the tip into position. This way you don’t get that “spurt” when you tip the bottle oveer to apply the cement. This tip really helps making clean job.

I made a measurement error too. I made the height measure for the new long pieces 1/16" too tall. It shows up here…

The effect is to raise the ends a little off the wood base, but it’s well supported by the long sides. Oh well…

After gluing, letting it set up about 1/2 hour, I was able to lift it, put it on the base and clean off any tape residue. It came out very clean and better than my past attempts.