probably 1m

Sorry… vertical depth. And width. I’m assuming you’d like them to replace the white drawers in the photo, the ones hanging below the work surface?

600-1000 mm wide, 1000 mm long and at least 200mm high.

I agree, I will change the desing to the same length.

I’ll will give it a try, thank you.

Using your bearing idea, I’d change the drawer design to something like this:

Great bunch of ideas! I have used linear motion bearings to solve lots of movement issues in stuff that I have built. They can be inexpensive and come in a large variety of sizes. I think they are worth checking out for your application

First test is coming closer…

Two different approaches, one for the smaller drawers:

and one for the big ones…

Are your drawers going to be full extension or 3/4 extension? Interested in seeing your solution for stops so you do not pull out the drawers unintentionally. thanks for the progress updates

Not full extension but something like “as far as possible”, I will start without stops and will add them later if neccessary…

Some updates…

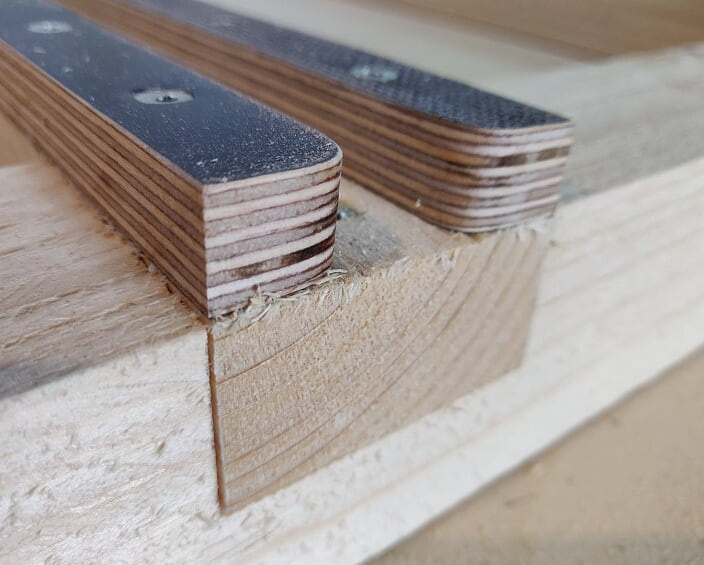

The worktop will be a torsion box construction…

Like the torsion box design, but would have used 3/4 appleply for the ribs, hard to get straight, square 2 x’s

I will start without stops and will add them later if neccessary…

hahahha…You might wanna upgrade your health insurance and specify “shin replacement” cover.

Are you set on a torsion box design? It looks like a lot of work and potential to become “wobbly”… why not just use a couple of layers of MDF or particleboard (with a top layer of hardboard/HDF which you can replace if when gets old?

I’ve never seen a compressor in a drawer…that’s …unique ![]()

Torsion boxes are incredibly strong, stable and light weight. We use 1" ply rips for the ribs then glue on the ply or MDF faces. They never give us any problems.

As for the drawer stops I am thinking steel toed boots until you have stops in place.

Thanks for the progress pictures

Great progress reports.

Draw fronts look like 9mm Siberian Birch ply? Osmo oil?

I agree with jwarshafsky: 24mm (or 1") ply rips for the skeleton make for a more stable torsion box. Pine will likely move and twist over time. It depends on your tollerance and budget I suppose.

I don’t think we’ve seen any of your tasty model render’d views of your bench yet!

Or maybe all the photos aren’t photos!.. ![]()

12mm with Clou oil ![]()

Is this your top, or something you plan to copy?

It’s my (half finished) version, I’ve added an OSB at the bottom in the meantime…