Hi @kengey and thanks to @MikeWayzovski for pushing forward all the info he always does about Sketchup and BIM. It’s always very insightful.

I’d like to pose some questions to @kengey if this 3DBI is able to keep up with changes to the model and track, for instance, the changes in the design of elements, and update the data and 3D model being shown during the development of the project.

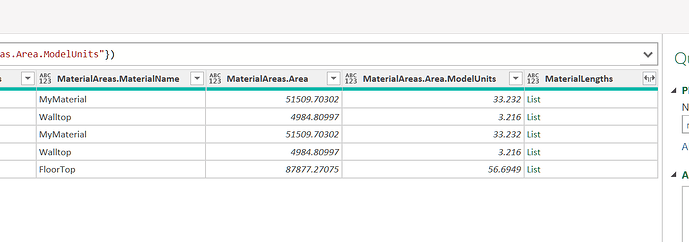

I really like how data is being displayed in Microsoft BI but What I’m concerned is also about standard output. So I’d also like to know if this could be used to create static surveys for quantity take offs, organized by types, like walls, ceilings, floors, and unique object like cabinets, kitchen, sinks, and so on as well as if it could create area reports, gross floor areas, per room, per floor, per building and such info.

I’d like to have a method that would keep up with building design and be able to extract all the info I need from the model, at any time, in an organized fashion, but also a way to infer data that can’t be modeled as it would be too cumbersome.

Specififally I’d like to know if this requires special model organization and detail to work well. I understand that a column or a slab, can be represented by a solid object, however, a layered wall or finishes to the slab, are too complex to be fully modeled.

How can we organize the model to represent all the layers of a roof, or wall, or floor, without having to model them?

Is this possible with this extension and, if so, how can we inform Sketchup and 3DBI about that?

Example:

A slab would be represented by a single solid volume. If it’s plain concrete this volume as a direct relation to the report and price. If it’s multilayered, with insulation, waterprofing, roof tiles and whatnot, ideally it is still a simple solid in sketchup that represents all of these layers. The volume of this model, cannot represent that and modelling all layers will make the model impossible to handle. How to solve this with 3DBI?

It would also be important that, each time I would have the work of inputing the info I’d need, I wouldn’t have to redo that work later on, and somehow it would be flexible enough to keep adapting to the added level of detail of following stages. This detail could be due to added detail of the model, but also added layers to the description of it’s element, description that would each have to be accounted for and assigned to costs.

Example: if we need an extra coat layer on a wall, we would ideally add it to that wall, and multiply the wall area by the coat cost. This new info on the wall composition can’t be modelled or shouldn’t be modeled, however it should be added to cost.

So, for this to be useful for us, it shouldn’t be limited to a new way of showing data (which is very interesting), but would need to be able to create standard take offs in excel and be very flexible in how it measures/reports items from the model and would need allow us to keep adding info, as the design progresses, without loosing previous info, but it would also need to be very flexible and accurate on how it reports volumes, areas, lenghts and take into account how and what each element of the model represents.

I hope the questions being raised here are not too confusing, but I really hope they can be answered by your plugin.

Thanks in advance,

João