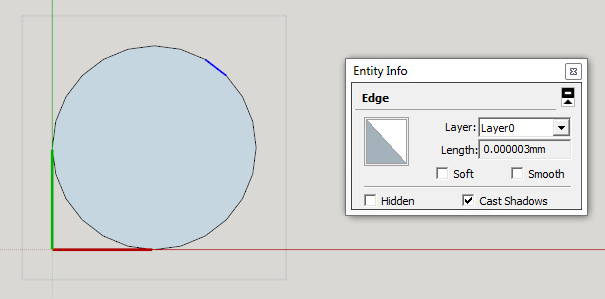

The minimum tolerance doesn’t matter. In an output for CNC it doesn’t matter if a redundant point is .00001" from the other point or .0001". It’s still a redundant point that creates errors. Or if you push/pull a plane all the way through. If you’re object is .720000" thick and it only pushes .719999…it’s not going all the way through. The difference between existence and non-existence. It’s pretty huge. I’m now redrawing 2 days worth of work for these crazy complex doors.

Also speaking from the perspective of someone that does CNC commercially. It triples the amount of time when some one drops off an erroneous file that requires hours or redrawing (often from scratch). I usually charge a lot for that or turn them away.

SketchUp for fantasy is one thing, but if you’re actually making things and you’re in a workflow with other people and other software you have to be extremely meticulous.