The team’s printer.

Looks like 80/20 aluminum extrusions. Worked with that much? Someone at my makerspace said it can get kinda pricey.

We do use quite a bit of 8020 extrusion in the robots. It does get pricey but it’s easier to work with when you need to make quick changes during the early design phase. Unfortunately we don’t have a decent machine shop so making parts out of aluminum bar and tube stock isn’t really feasible. We do end up reusing a fair amount of it. We expect the drive modules to not only make repairs easier during competitions but also to be usable from one year to the next so that will help reduce the amount of new material we need and reduce the amount of engineering we have to do.

A little off topic (but also on topic in a sense):

At first as a FIRST mentor I would hang out with the programmers. They did find someone much better at that than me, so I started to help the animators. Back then Autodesk sponsored the animation part of the competition, and so the students would use 3DS Max for their work. But I did use SketchUp, Adobe Director, and Unity to do some simulations.

This YouTube link will show some of the animations they did: https://www.youtube.com/results?search_query=694+stuypulse+animation

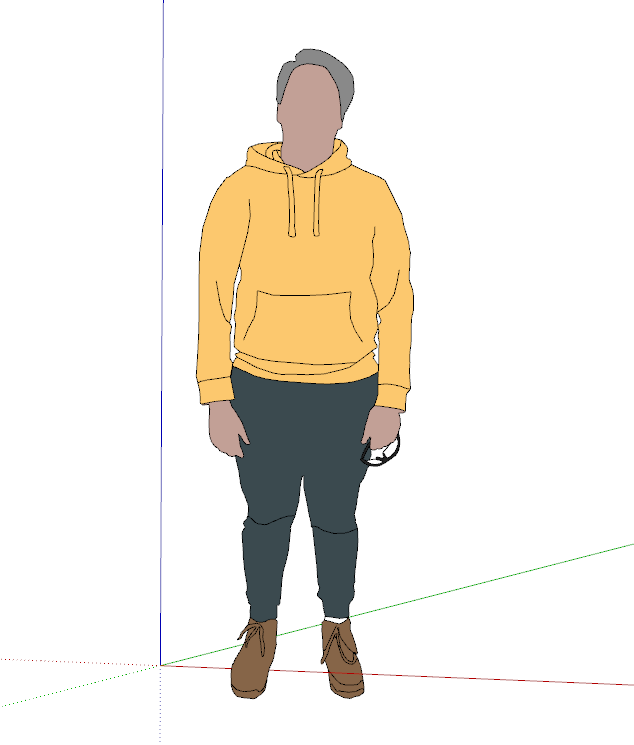

One of the mentors 3D printed the parts for the playing field for this year’s challenge. I took a photo of one of the senior student members of the team and made a flat one of him,

We 3D printed him to fit the scale of the playing field to lend an bit of scale.

Still need to print out stickers of him to apply front and back.