Is there a reason I’m not seeing half the conversation in this thread?

Perhaps you are imagining it.

I’m only guessing because the answers are few and far between.

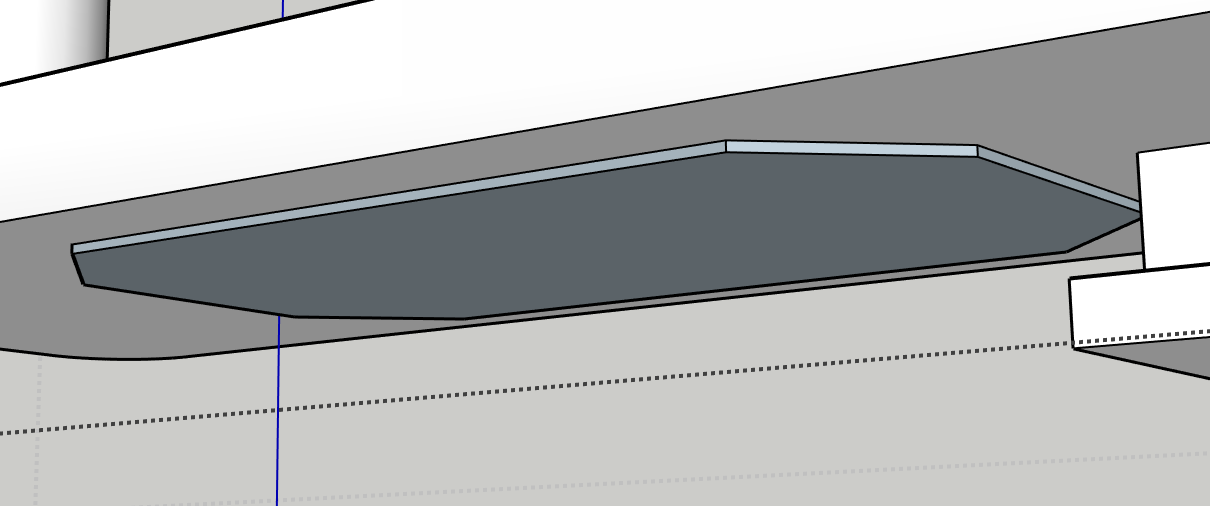

I tried getting it finished, but the STL it makes doesn’t want to work. I tried intersecting faces but to no avail.balljoint1b.skp (724.9 KB)

That’s exactly what I want to do Box. You make it look easy ![]()

I had issue years ago with an stl model of a boat hull that had a few faces reversed. Facet data matters.

Your model still has some rounded corners that are not tangential. not sure if that matters.

It’s too late at night for me to try to explain what was wrong.

But basically, reversed faces and a mixture of groups and raw geometry.

It simply wasn’t a solid and wouldn’t export as a suitable .stl

Try this.

balljoint1box.skp (141.8 KB)

An StL (“StereoLithography”) file is a triangular representation of a 3-dimensional surface geometry. The surface is tessellated or broken down logically into a series of small triangles (facets). Each facet is described by a perpendicular direction and three points representing the vertices (corners) of the triangle. These data are used by a slicing algorithm to determine the cross sections of the 3-dimensional shape to be built by the fabber.

If a face is reversed…your printer (or cnc as the case might be) probably doesn’t recognize the face as being there because the normals are absent…or hidden.

Wow. Thank you Box. That works almost perfectly. Made a very small tweak to the mounting post and it’s running great.

One more question…how would you elongate the offset? I haven’t been able to do it yet.

It’s just edges and faces, geometry, grab hold of it and move it.

Was able to extend it, but twhne I went to thicken it and add a vent, it doesn’t seem to like it.balljoint1c.skp (148.6 KB)

Well you had my undivided attention for a while but now I’m at sea for a few days so I only have a phone for now. Someone else will come along I’m sure.

But basically just look at the geometry and work with it. Use View/Hidden geometry to see what are single faces that you can use Pushpull on or select and move etc. It’s not a mystery, everything is made of edges and faces.

Yeah, but it should be 3mm, and for some reason, when I put that in, it goes over.balljoint1c.skp (170.3 KB)

That’s because the base is only 2.8mm thick!

Wow. How’d you get that? When I did it you can see it’s 3mm

Increase the digits precision in model info units.

Yep that did it. Thank you

This topic was automatically closed 91 days after the last reply. New replies are no longer allowed.